CANALTA FLOW MEASUREMENT is a privately held Canadian company that began operations in 1986 as an instrumentation and electrical contractor. Since 1991, the focus has been on the manufacture of industrial control and measurement equipment. Canalta has been supplying industry worldwide with quality double block & bleed, dual and single chamber orifice fittings, meter runs, flow conditioning accessories and parts for more than fifteen years. Canalta meter runs and orifice fittings are currently in service on every continent and in many off-shore production facilities. We have provided effective flow measurement equipment to companies large and small across a variety of industries, from oil and gas to food service. Canalta has also taken an industry-leading role in orifice meter innovation by improving the reliability and safety of orifice-based metering packages.

Today, the Canalta team comprises roughly 250 members spread across the globe, with our headquarters in Red Deer, AB Canada. Here we maintain primary warehouse and manufacturing facilities with full in-house design, full machining, pressure welding and pipe honing capabilities. Red Deer is also home to our main direct sales and corporate offices.

In recent years we have added warehousing facilities in Texas, India and Korea, as well as direct sales branch offices in Dallas, Buenos Aires, Singapore and Suffolk, UK. We have also seen growth in the network of experienced firms representing and servicing our product around the world. This outward expansion has been undertaken in order to provide our growing customer base with cost-effective, high quality measurement equipment as efficiently as possible.

Throughout our history we have maintained a dedication to quality, service and delivery without sacrificing our competitive price point. Our ISO 9001 registration, PED certification, comprehensive quality control program and expanding business reflect this dedication, and we are committed to maintaining these values in the future.

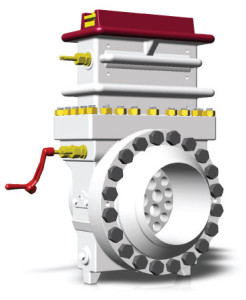

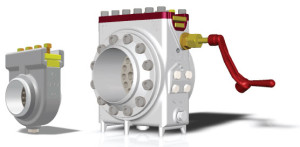

CANALTA DUAL CHAMBER ORIFICE FITTING

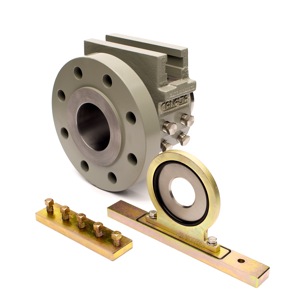

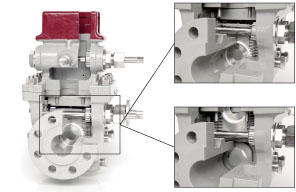

The Canalta Dual Chamber Orifice Fitting allows for accurate flow measurements, orifice plate inspection and changing without breaking apart or depressurizing the flow line. (Photo) CANALTA SINGLE CHAMBER ORIFICE FITTING The Canalta Single Chamber Orifice Fitting is designed and constructed to allow for ease of orifice plate replacement or inspection after depressurization. (Photo) CUSTOM METER RUNS Canalta fabricates custom meter runs for all of our orifice fitting models and a variety of other metering applications. Whether the size is 2” or 30”, high or low pressure, wet, dry or corrosive service, we can put together a custom meter run package that meets your specification or performance needs and perfectly matches your Canalta Orifice Fitting or other specialized metering device. (Photo) Canalta Contour™ Series flow Conditioners. These isolating flow conditioners incorporate a non-protruding HNBR seal around the downstream face to prevent bypass leakage, and are available in a number of industry accepted plate geometries, from the Zanker to the #50-style and more. The Canalta Contour FCH™ Flow Conditioner Housing brings the ease, safety and practicality of inspecting and changing an orifice plate to the flow conditioner. This long overdue concept allows for regular inspections of the flow conditioner without breaking apart the flow line. The Canalta Contour FCH™ allows the operator to easily perform flow conditioner inspection and maintenance on the same regular schedule as the orifice plate. With this innovative, newly patented design, you can be sure that your flow profile has not been degraded by damage, blockage or residue accumulation. KEY FEATURES

ORIFICE FITTING PARTS & KITS Everything needed to keep Dual and Single Chamber Orifice Fittings operating accurately and efficiently. Parts are available for standard or corrosive service requirements, line sizes 2″ through 30″, ANSI ratings 150 through 2500. Canalta Orifice Fitting Repair Kits include a full complement of orifice fitting parts, allowing for a complete rebuild of the orifice fitting or replenishment of spare parts inventory. These kits are available with 4130 carbon steel internals for standard applications, or 316 stainless steel internals for extreme corrosive applications. All repair kits include high grade HNBR internal seals and are packaged in a sturdy resin case for easy storage or transport. Repair kits for Daniel* Junior and Senior Orifice Fittings are also available, substituting Garlock gaskets for the standard Canalta body, valve seat and seal bar O-ring seals. These parts can also be supplied on an individual basis. Contact us for full details on our servicing of Daniel product lines. ORIFICE PLATES AND SEALS A full range of standard concentric universal and paddle plates, orifice plates for special applications and orifice plate seals to match your specific process and service environment. All orifice plates comply with AGA-3 / API 14.3 or ISO 5167-1 requirements for maximum accuracy. Canalta can also provide Orifice Fitting Inspection Reports, guaranteeing quality and performance. |

|